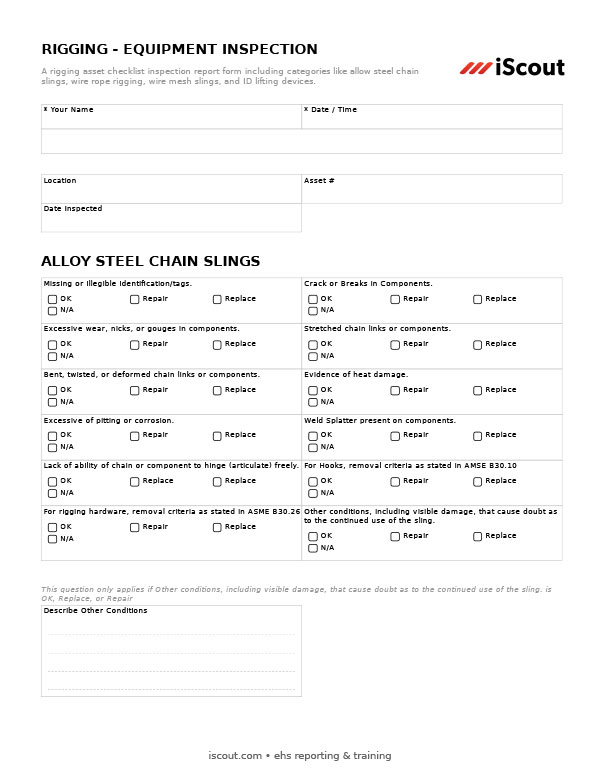

Rigging - Equipment Inspection Form

A rigging asset checklist inspection report form including categories like allow steel chain slings, wire rope rigging, wire mesh slings, and ID lifting devices. Checkout the Forms Library »

What is a Rigging Inspection Checklist?

Rigging creates a wide variety of potential safety hazards for a job site including asset drops, uncontrolled movements and swings, electrical hazards, pinch points, along with many others. The assessment is designed to identify potential hazards before the cause an incident. For this assessment, each question must be scored by the observer as OK, Needs Repair, Needs Replacement, or N/A.

Alloy Steel Chain Slings

- Missing or illegible identification/tags.

- Crack or Breaks in Components.

- Excessive wear, nicks, or gouges in components.

- Stretched chain links or components.

- Bent, twisted, or deformed chain links or components.

- Evidence of heat damage.

- Excessive of pitting or corrosion.

- Weld Splatter present on components.

- Lack of ability of chain or component to hinge (articulate) freely.

- For Hooks, removal criteria as stated in AMSE B30.10

- For rigging hardware, removal criteria as stated in ASME B30.26

- Other conditions, including visible damage, that cause doubt as to the continued use of the sling.

Wire Rope Sling/Rigging

- Missing or illegible identification/tag.

- Broken Wires

- Severe localized abrasion or scraping

- Kinking, crushing, bird caging, or any other damage resulting in damage to the rope structure.

- Evidence of heat damage.

- End attachments that are cracked, deformed, or worn to the extent that the strength of the sling is substantially affected.

- Severe corrosion of the rope, end attachments, or fittings.

- For hooks, removal criteria as stated in ASME B30.10.

- For rigging hardware, removal criteria as stated in ASME B30.26.

- Other conditions, including visible damage, that could cause doubt as to continued use of the sling.

Wire Mesh Slings

- Missing or illegible sling identification/tag.

- Broken weld or broken brazed joint along the sling edge.

- Broken wire in any part of the mesh.

- Reduction in wire of 25% due to abrasion or 15% due to corrosion.

- Lack of flexibility due to distortion of the mesh.

- Distortion of the choker fitting so the depth of the slot is increased by more than 10%.

- Distortion of either end fitting so the width of the eye opening is decreased by more than 10%.

- A 15% reduction of the original cross-sectional area of any point around the hook opening of the end fitting.

- Visible distortion of either end fitting out of its plane.

- Cracked end fitting.

- Slings in which the spirals are locked or without free articulation SHALL not be used.

- Fitting that are pitted, corroded, cracked, bent, twisted, gouged, or broken.

- Other conditions, including visible damage, that cause doubt as to the continued use of the sling.

ID Lifting Devices/Hooks

- Devices/Hooks that show pitting, corroding, cracked, bent, twisted, gouged, or broken/loose components or welds.

- Evidence of heat damage.

- Bent, twisted, or deformed chain links or components.

- Lack of ability of chain or component to hinge (articulate) freely.

- Broken weld or broken brazed joint anywhere on the ID Lifting Device/Hook.

- Other conditions, including visible damage, that cause doubt as to the continued use of the device/hook.

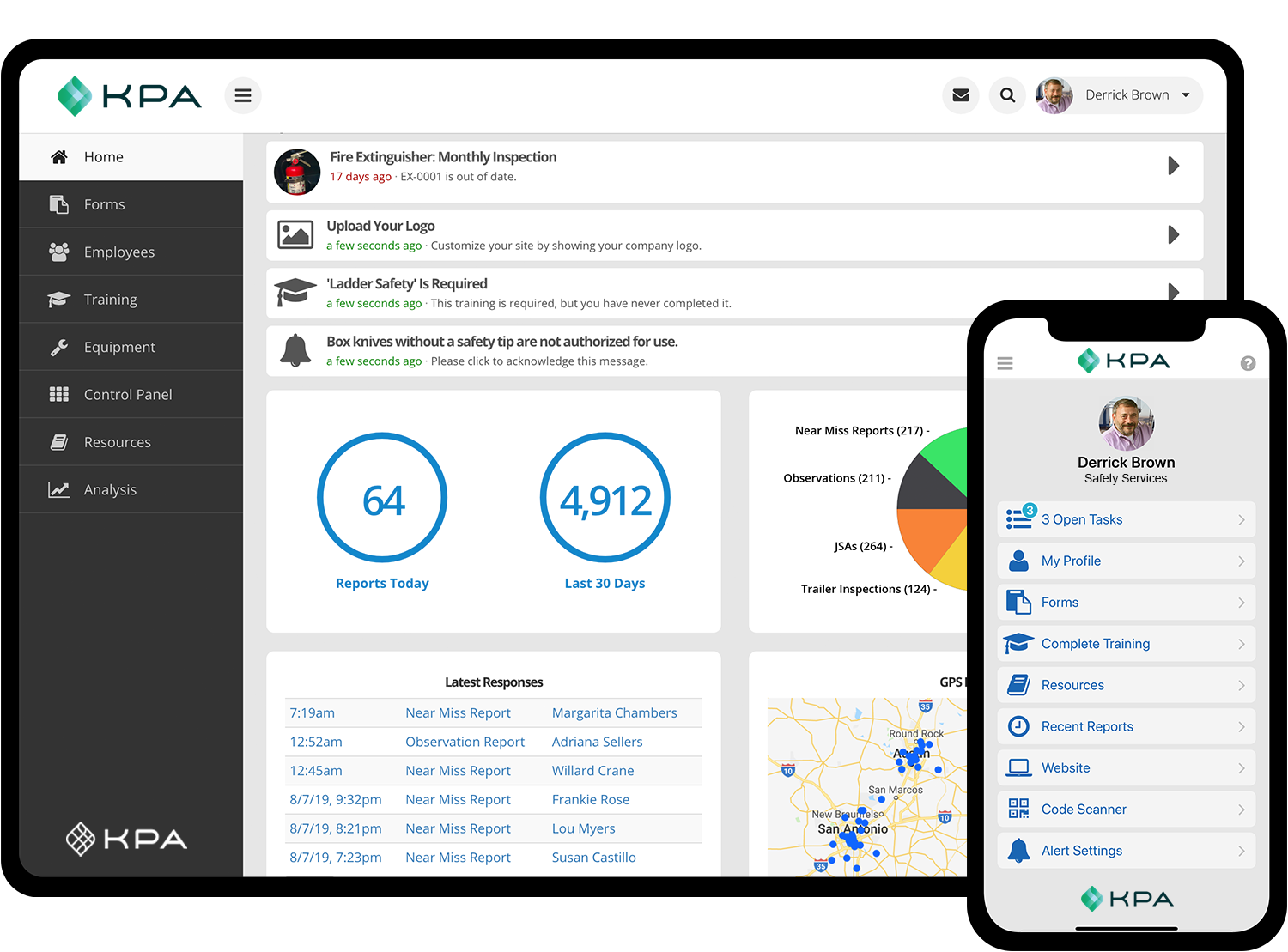

This form is a sample report which can be imported into your KPA Flex account. All forms including this one can be easily modified to fit your organization's policies and procedures.

Don't have a KPA Flex account? Download the printable Rigging - Equipment Inspection PDF form so your team can fill out a paper copy.

Top Features of KPA Flex Reporting

Check out the Forms Overview or learn about specific features:

Form Builder »

Start from a pre-built template or design your own form from scratch.

Offline / Mobile Reporting »

Once team members have downloaded the app, they can fill out reports offline - including attachments! The report will automatically upload once connectivity resumes.

Follow-Up Tracking »

Assign follow-ups within a report and track incomplete items.

Permissions »

You decide who can submit reports, view responses, and more.

Alerts & Notifications »

Setup individual or group notifications for certain reports. For example, you may want notifications for critical issues but not minor ones.

Analysis Tools »

KPA Flex automatically generates rich analytic tools so you can filter, visualize, and export all the data you're collecting.

Participation Reports »

Run participation reports to see who is submitting reports and when they're being submitted.

Electronic Signatures »

Collect electronic signatures when your team fill out reports.

Multilingual »

Forms filled out through the web browser can be automatically translated into 100+ languages.

Revision History

As your team edits a report, the system will automatically track what was changed, the author, and the date.

Data Lists

As projects, locations, etc change, the form will automatically update to include the latest options.

Auto-Hiding Fields

Clicking "Does Not Apply" dozens of times is counter-productive. Instead, hide questions that don't apply.

Sub-Reports

Some forms can be extremely complex, but that's no problem in KPA Flex. Setup sub-reports to make it easier to fill out in sections.